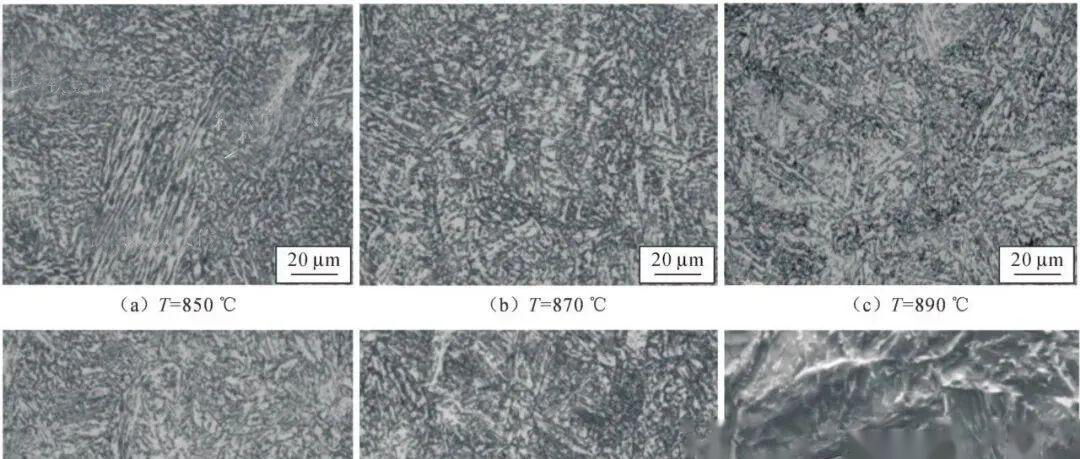

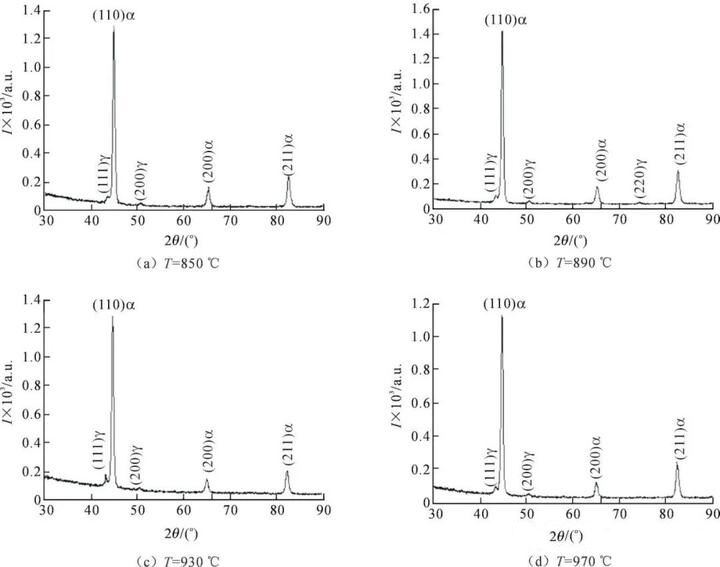

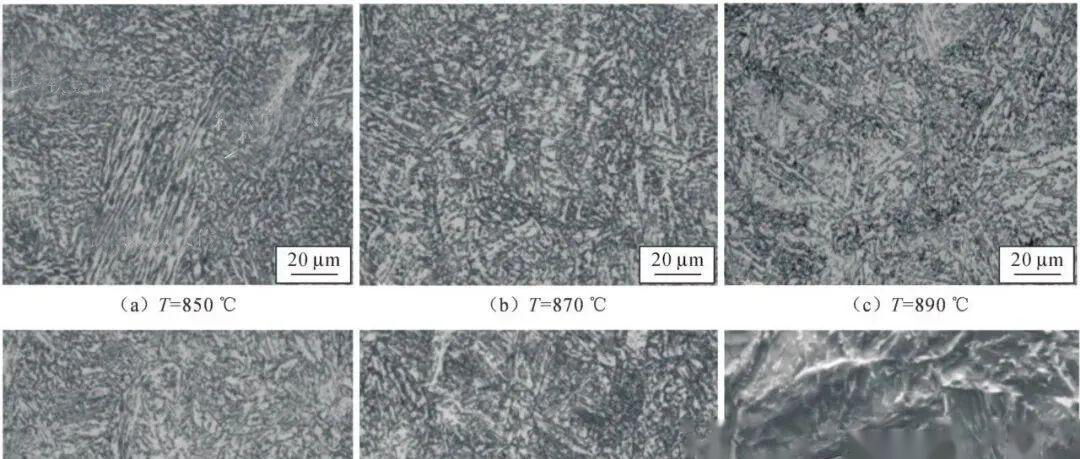

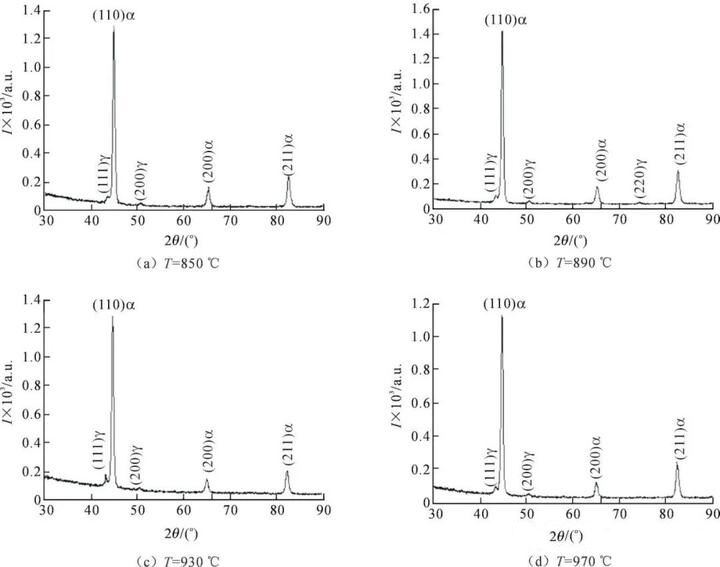

Understanding the influence of normalizing temperature on the microstructure and properties of high-strength bainitic steel pipe is crucial for optimizing its performance in various applications. In this study, a series of heat treatment experiments were conducted to investigate the impact of different normalizing temperatures on the mechanical properties and microstructural evolution of newly developed bainitic steel pipe. Tensile and impact tests were performed to evaluate the mechanical properties, while scanning electron microscopy (SEM), optical microscopy, and X-ray diffraction (XRD) were employed for microstructural analysis.

Steel pipe is a vital component in many industrial applications, and its mechanical properties play a critical role in determining its suitability for specific environments. Heat treatment is commonly used to enhance the mechanical properties of steel, and understanding the effect of normalizing temperature on the microstructure and properties of high-strength bainitic steel pipe is essential for optimizing its performance. This study aims to investigate how different normalizing temperatures affect the mechanical properties and microstructural characteristics of bainitic steel pipe.

Experimental Procedure:

The experimental material used in this study was a newly developed high-strength bainitic steel pipe, manufactured through a series of processes including melting, refining, casting, and hot rolling. Tensile and impact tests were conducted on specimens subjected to different normalizing temperatures, and the microstructural evolution was analyzed using SEM, optical microscopy, and XRD. The normalizing temperatures ranged from 850°C to 970°C, with a holding time of 30 minutes followed by air cooling.

Results and Discussion:

The results revealed that as the normalizing temperature increased, the tensile strength of the bainitic steel pipe exhibited a decreasing trend, albeit with minimal variation. However, at a normalizing temperature of 930°C, the pipe demonstrated optimal mechanical properties, including higher tensile strength, elongation, and section shrinkage, along with maximum impact energy. Microstructural analysis indicated that heating the steel pipe to 930°C resulted in a finer microstructure compared to higher temperatures, where the proportion of plate-like bainite increased, leading to coarsening of the structure.

Conclusion:

In conclusion, the optimal normalizing temperature for the high-strength bainitic steel pipe was determined to be 930°C, which resulted in improved mechanical properties and a refined microstructure. These findings provide valuable insights for the development and optimization of heat treatment processes for bainitic steel pipe, with potential applications in various industrial sectors. Further research could focus on exploring the relationship between microstructure and mechanical properties in more detail, to enhance the understanding of bainitic steel behavior under different heat treatment conditions.