- Home

- Products

- Tags

- Pipe Grades

- Pipe Sizes

- Pipe Ends

- Pipe Lengths

- Pipe Standards

- Pipe Schedules

- Pipe Surface Finish

- ASTM Material

- Pipe Machine Motor

- Pipe Machine Speed

- Pipe Machine Chuck

- Pipe Machine Capacity

- Pipe Machine Size

- Pipe Machine Use

- Pipe Machine Weight

- Pipe Wall Thickness

- Pipe application

- Pipe range

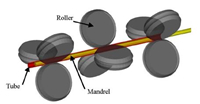

- Manufacturing Method

- Pipe joint

- Pipe class

- Performance

- Pipe Length

- Pipe Pressure

- Pipe type

- Services

- Industries

- About

- News

- Contact