2. Economic analyses of pipes based on the internal optimized anti-corrosion coating

Although epoxy ceramic internal anticorrosion will increase the investment, its roughness is small. The pipe diameter can be appropriately reduced, thereby reducing the unit price of pipeline construction and installation. In order to further compare and analyze the economy of steel pipes and ductile iron pipes, taking the East to West Water Diversion Project 5 in the Miyun District as an example, the economic analysis of pipes based on internal anti-corrosion optimization of pipe diameters is carried out.

2.1 Basic analysis conditions

The East to West Water Diversion Project in the Miyun District gets water from the Shachang Reservoir by pressure pipelines from east to west through the Hongmenchuan River and Chao River, passing through the Miyun Airport, Yexianta Park, etc., and then transport to the Bai River in the Miyun District. The total length of the water delivery pipeline is 20.55km and the delivery amount is 1.15m3/s; the normal operating water level of the Shachang Reservoir is 165.50m; the elevation of the Bai River estuary is 78m, and the effective terrain elevation difference is 87.5m. The design working pressure is 0.7MPa, and the test pressure is 1.2MPa.

According to the specific situation of the East to West Water Diversion Project in the Miyun District, under the premise of meeting the pipeline design function, the different types of pipes and their internal anti-corrosion coatings are as follows:

1. Cement mortar internal coatings are adopted for a steel pipe with a size of DN900 and wall thickness of 9mm; the roughness is 0.0125.

2. Epoxy ceramic internal coatings are selected for for a steel pipe with a size of DN800 and wall thickness of 8mm; the roughness is 0.009.

3. Cement mortar internal coatings are used for Grade K9 ductile iron pipes whose diameters are DN900 and the roughness is 0.0125.

4. Epoxy ceramic internal coatings are chosen for Grade K9 ductile iron pipes with a diameter of DN800; the roughness is 0.009.

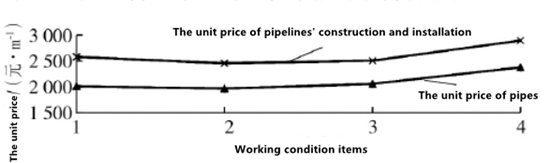

See the Table 2 and Figure 3 for specific economic analyses.

Table 2 Statistics of working conditions based on the East to West Water Diversion Project in the Miyun District

| The types of pipes and their coatings |

Specific definitions (pipe materials plus internal anti-corrosion coatings) |

Roughness

|

Velocity/(m.s-1)

|

Total head losses/m

|

| 1 |

Steel pipes with a size of DN900 (t being 9 mm) plus cement mortar |

0.012 5 |

1.81

|

85.81 |

| 2 |

Steel pipes with a size of DN800 (t being 8 mm) plus epoxy ceramic |

0.0090 |

2.29

|

83.37 |

| 3 |

K9 ductile iron pipes with a size of DN900 plus cement mortar |

0.012 5 |

1.81 |

85.81 |

| 4 |

K9 grade ductile iron pipes with a size of DN 800 plus epoxy ceramic |

0.0090 |

2.29 |

83.37 |

2.2 Analysis results

According to the Figure 3, steel pipes with a size of DN800 adopting epoxy ceramic internal anticorrosive coatings are the most economical in the Miyun East to West Water Diversion Project, while ductile iron pipes with a size of DN800 which are coated with ceramic internal anticorrosive coatings are the least economical.

Based on the applicable conditions of the East to West Water Diversion Project in the Miyun District, it was concluded that:

1. Taking either the unit price of pipes or the unit price of pipelines' construction and installation into account, epoxy ceramic internal coated steel pipes are the most cost-effective, followed by steel pipes with cement mortar internal coatings and ductile iron pipes with epoxy ceramic internal coatings are the least economical.

2. Reducing diameters of steel pipes can reduce the construction investment by adopting the epoxy ceramic internal anti-corrosion coatings with smaller roughness. However, ductile iron pipes with epoxy ceramic internal coatings can not effectively make your investment less.

Figure 3 Unit price analyses based on the East to West Water Diversion Project in the Miyun District

2.3 Summary

According to the East to West Water Diversion Project in the Miyun District, from an economic point of view, steel pipes with epoxy ceramic internal coatings should be preferred under the same applicable condition of having small pipe diameters. Epoxy ceramics coatings have a smooth surface and low roughness, which can effectively reduce the diameter of steel pipes. Although the investment in the epoxy ceramics coating increases, the overall construction and installation costs of pipelines can be reduced. If conditions permit, the ductile iron pipes with internal cement mortar coatings can be appropriately selected after a comparison. Furthermore, if the pipe diameter is relatively large, epoxy ceramic internal coated steel pipes should be preferred.

3. Conclusion

(1) In the Beijing area, when the pipe diameter is less than or equal to 800mm, the ductile iron pipe has more economic advantages than the steel pipe, and the ductile iron pipe with cement mortar internal coatings is the most cost-effective; when the pipe diameter is greater than 800mm, the steel pipe has more economic advantages. The steel pipe with cement mortar coatings is the most cost-effective.

(2) For the same project, the use of epoxy ceramic internal coated steel pipes with smaller roughness can effectively reduce diameters of steel pipes and achieve the purpose of reducing construction investment, while the use of epoxy ceramic coated ductile iron pipes can not effectively reduce the investment.

(3) Only from an economic point of view, the steel pipe with epoxy ceramic coatings for the same project is the most cost-effective.

(4) Steel pipes are the most suitable when epoxy ceramic internal coatings are required due to high requirements for internal anti-corrosion.