High-temperature oxidation and corrosion of the inner wall are among the main factors causing the failure of supercritical power station

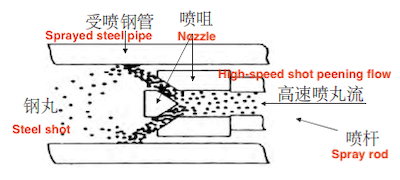

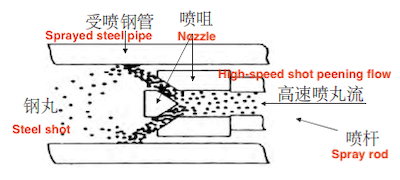

boiler tubes. To extend the service life of boiler tubes and meet rising steam temperature requirements, current measures include using materials with enhanced corrosion resistance, improving material structure and performance, and applying technical surface treatments. Shot peening of the inner wall of steel pipes is one of the most effective and economical surface treatment methods (Figure 1). This process refines the surface grains of steel pipes, forms high-density dislocations, stacking faults, and other structural hardening layers, provides a favorable diffusion path for Cr elements, reduces the diffusion rate difference between Fe and Cr elements, and forms a dense Cr oxide film layer at high temperatures. The method of enhancing oxidation resistance in steel pipes through internal shot peening is increasingly used in power station industries both domestically and internationally.

Figure 1 Shot peening on the inner wall of a steel pipe

SA213M S30432 austenitic stainless steel boiler tubes are currently the primary material for high-temperature components, such as supercritical boiler superheaters and reheaters, due to their excellent high-temperature creep resistance and oxidation resistance. The S30432 austenitic stainless steel boiler tubes studied in this paper were manufactured by a steel plant and have been widely used by major boiler manufacturing companies in China.

The main mechanism for improving the oxidation resistance of boiler tubes through internal shot peening is as follows:

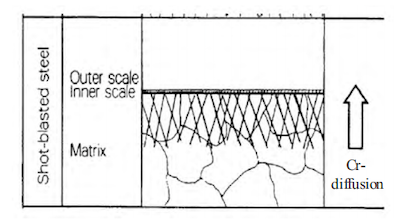

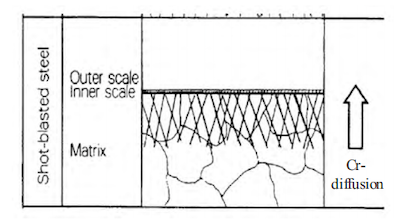

(1) The difference in the diffusion rates of Fe and Cr is an important factor that affects the composition of the surface oxide film. The high-temperature oxide film formed in the working environment of supercritical power station boiler tubes at 600°C is mainly composed of Fe₃O₄ and (Fe, Cr)₃O₄. Compared to Fe²⁺ and Fe³⁺, the diffusion rate of Cr³⁺ to the oxide film/gas interface is much slower. The farther one is from the oxide film/substrate interface, the lower the Cr concentration becomes, resulting in the outermost layer of the oxide film being primarily iron oxide. The iron oxide continues to grow and peel off, which accelerates corrosion of the inner wall. The diffusion of Cr primarily occurs through short-circuit diffusion. Internal shot peening can refine the surface grains, create high-density dislocation and stacking fault structures, increase short-circuit diffusion channels, such as grain boundaries and subgrain boundaries, enhance the Cr diffusion flux (Figure 2), form a Cr-rich oxide layer, alter the composition of the surface oxide film, and reduce the corrosion rate.

Figure 2 The Cr element diffusion channels in the shot peening layer on the inner wall of the steel pipe

(2) In a high-temperature oxidizing environment containing water vapor, the oxidation process of Fe-Cr alloys is significantly accelerated. The primary reason is that water vapor molecules adsorbed on the surface of the oxide film react with Fe ions from the inner and outer oxidation interfaces, generating FeO and free hydrogen, which significantly accelerates the decomposition of the iron-chromium oxide film. After shot peening, the original oxide film becomes uniform and dense, which slows the reaction rate between H₂O and iron-chromium oxide.

H₂O + Fe²⁺ + 2e- → FeO + H₂

H₂ → 2H⁺ + 2e⁻

(Fe, Cr)₃O₄ + 8H⁺ → Fe³⁺ + Fe²⁺ + Cr³⁺ + 4H₂O

From the above analysis, it can be concluded that the greater the effective depth of the shot-peening layer in the boiler tube, the denser the original oxide film becomes, the more uniform and refined the grains are, and the better the high-temperature corrosion resistance. At present, the main methods for evaluating the depth, microstructure, and other properties of the shot-peening layer in the steel tube are the metallographic method and the microhardness method. This paper uses both methods to study sample tubes obtained through different internal shot peening for S30432 boiler tubes, with the aim of selecting a more optimal process to improve the quality of the internal shot-peening layer.

The basic parameters of the shot-peening equipment used are as follows: a maximum working pressure of 1.4MPa, a shot-peening flow rate of 10–20 kg/min, an automatic spray gun feed speed of 20–100 cm/min, a shot-peening trolley speed of 0.2–3 m/min, and a shot material consisting of special 304 stainless steel shot with a particle size of 0.3–0.7 mm. The object of shot peening is a 51 mm × 11 mm S30432 austenitic stainless steel boiler tube, formed by hot extrusion and cold rolling, with a clean, defect-free inner surface (Figure 3). After shot peening, the inner surface remains clean and undamaged, and the shot-peening layer is uniform (Figure 4).

Figure 3 Inner steel pipe state of the inner surface before shot peening

Figure 4 Inner steel pipe state of the inner surface after shot peening

Different shot-peening processes were designed for testing, and the effects of working pressure, spray gun feed speed, shot flow rate, and shot-peening frequency on the results were tested individually. Metallographic inspection and cross-sectional hardness curve analysis were performed on the samples with the best results to verify whether the depth of the shot-peening layer and the hardness change values met the standard requirements.

Table 1 Shot peening test parameter design

| Sample Number |

Working Pressure (MPa) |

Gun Feed Speed (cm·min⁻¹) |

Shot Flow Rate (kg·min⁻¹) |

Shot Peening Times |

| 1-1 |

1.0 |

50 |

15 |

2 |

| 1-2 |

1.25 |

50 |

15 |

2 |

| 1-3 |

1.40 |

50 |

15 |

2 |

| 2-1 |

1.25 |

35 |

15 |

2 |

| 2-2 |

1.25 |

70 |

15 |

2 |

| 3-1 |

1.25 |

50 |

11 |

2 |

| 3-2 |

1.25 |

50 |

18 |

2 |

| 4-1 |

1.25 |

50 |

15 |

1 |

| 4-2 |

1.25 |

50 |

15 |

3 |

According to industry standard DL/T 1603-2016, Technical Conditions for Quality Inspection and Acceptance of Shot Peening Layer on the Inner Wall of Austenitic Stainless Steel Boiler Tubes, a Vickers microhardness tester was used, following national standard GB/T 4340.1, with a test load force of 1.96 N and a loading time of 10–15 seconds.

Inspection position and number of measuring points: The transverse annular specimen was randomly marked with four inspection positions at 3 o'clock, 6 o'clock, 9 o'clock, and 12 o'clock (or 0°, 90°, 180°, and 270°) along the circumference. The shot-peening layer was tested at a distance of 60 μm from the inner wall surface. At least three microhardness values were measured at each inspection position, and the average value was taken as the hardness of that position. The base metal was tested for microhardness at half the wall thickness, with at least three values measured and the average value taken.

Table 2 Shot peening hardness test data statistics (Hv0.2)

| Specimen Number |

3 o'clock |

6 o'clock |

9 o'clock |

12 o'clock |

Average Value |

Base Value |

Hardness Difference Value |

| 1-1 |

359.4 |

352.9 |

353.5 |

338.8 |

350.9 |

184.3 |

166.6 |

| 1-2 |

339.6 |

348.3 |

346.3 |

344.4 |

344.6 |

177.5 |

167.1 |

| 1-3 |

348.9 |

360.8 |

363.3 |

318.9 |

347.9 |

166.9 |

181.5 |

| 2-1 |

330.8 |

351.7 |

349.2 |

326.8 |

339.6 |

171.5 |

168.1 |

| 2-2 |

352.2 |

339.9 |

337.0 |

327.5 |

339.1 |

186.0 |

153.1 |

| 3-1 |

344.4 |

345.3 |

346.9 |

341.9 |

344.5 |

187.1 |

157.4 |

| 3-2 |

358.7 |

357.5 |

370.8 |

370.5 |

364.3 |

179.5 |

184.8 |

| 4-1 |

341.1 |

366.1 |

374.4 |

346.5 |

356.9 |

182.7 |

174.2 |

| 4-2 |

353.9 |

364.4 |

370.7 |

369.1 |

364.5 |

173.2 |

191.3 |

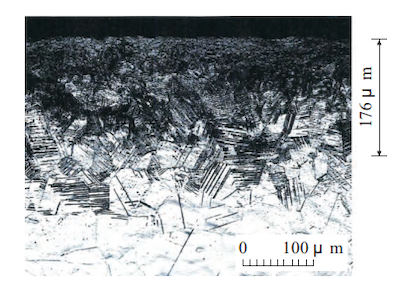

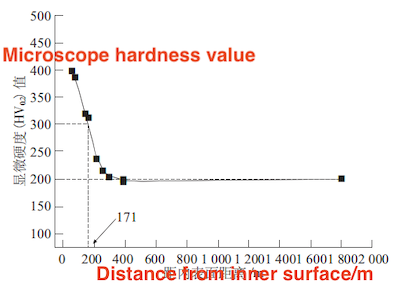

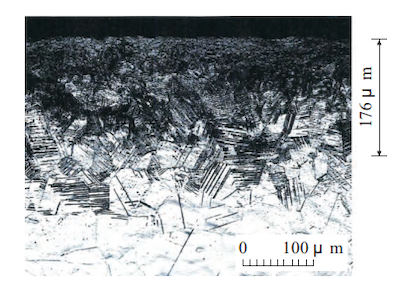

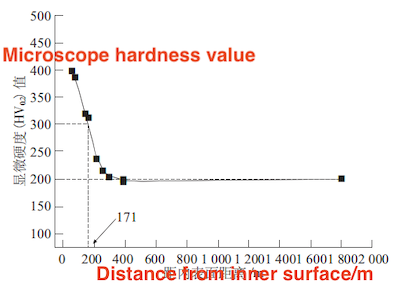

According to the test results, process parameters like working pressure, gun feed speed, shot flow rate, and shot peening times all impact the increase in microhardness of the shot peening layer. Upon analyzing each factor, the shot flow rate and shot peening times have the most significant impact; the impact of working pressure is minor, and the effect of gun feed speed is negligible. Comparing the shot peening effects under different process parameters, samples 3-2 and 4-2 demonstrate the best results. When other parameters remain constant, sample 4-2 was shot peened three times, which affects production efficiency. The effective shot peening layer depth of sample 3-2 was measured using the metallographic method, with results shown in Figure 5. The microhardness curve method was also used to measure the layer depth, and the sampling position and results are displayed in Figures 6, 7, and Table 3.

Figure 5 Metallographic method to measure the depth of the shot peening layer

Figure 6 Sampling position for microhardness test of shot peening layer of a single specimen (×200)

Figure 7 Microhardness test results of shot peening layer of a single specimen

According to industry standard DL/T 1603-2016, "Technical Conditions for Quality Inspection and Acceptance of Shot Peening Layers on the Inner Walls of Austenitic Stainless Steel Boiler Tubes," the requirements for the shot peening layer performance on the inner walls of austenitic stainless steel boiler tubes are as follows: The effective shot peening layer depth, measured using the metallographic method, must be no less than 70 µm; the effective shot peening layer depth, measured using the hardness curve method, must be no less than 60 µm. At a depth of 60 µm from the inner wall surface of the same cross-section of the shot-peened tube, the hardness value (HV), measured at 3:00, 6:00, 9:00, and 12:00 along the clock direction (or at 0°, 90°, 180°, and 270°), should be at least 100 higher than the hardness value of the base metal, and the difference in hardness values at the four positions must not exceed 50. For S30432 steel tubes, the hardness of the shot peening layer at 60 µm should be no less than 280 HV. From the above, it can be concluded that the effective shot peening layer depth of sample 3-2 is 176 µm (metallographic method)/171 µm (microhardness method), and the hardness of the shot peening layer at 60 µm reaches 364 HV. The shot peening effect is good, and the test results meet the standard requirements.

Based on the above comparative tests and analysis, the following conclusions can be drawn about the internal shot peening of S30432 austenitic stainless steel boiler tubes:

Working pressure, spray gun feed speed, shot flow rate, shot peening times, and other process parameters affect the increase in microhardness of the shot peening layer, with the shot flow rate and shot peening times having the most significant effects.

Table 3 Microhardness test results of shot peening layer of a single sample

| Sample Number |

Indentation Number |

Distance from Inner Surface (um) |

Test Results |

| 1-2 |

1 |

18.94 |

442.3 |

| 2 |

21.25 |

386.4 |

| 3 |

35.10 |

441.2 |

| 4 |

51.27 |

405.5 |

| 5 |

68.36 |

319.2 |

| 6 |

92.38 |

361.3 |

| 7 |

95.61 |

292.2 |

| 8 |

153.81 |

261.3 |

| 9 |

156.12 |

251.4 |

| 10 |

187.53 |

261.4 |

| 11 |

215.24 |

208.6 |

| 12 |

216.16 |

211.1 |

| 13 |

249.42 |

198.2 |

| 14 |

312.70 |

182.3 |

| 15 |

318.98 |

173.0 |

| 16 |

442.3 |

169.1 |

| 17 |

511.77 |

190.2 |

| Matrix |

1/2 Wall Thickness |

177.5 |

For products with specifications of 51 mm x 11 mm, using moderate working pressure, spray gun feed speed, higher shot flow, and two shot peenings can achieve better shot peening layer performance; however, increasing shot peening times further can improve results, but it will significantly reduce production efficiency and is unnecessary.

Spray gun feed speed and shot peening times are the primary parameters affecting shot peening production efficiency. Increasing the spray gun feed speed and the number of shot peenings appropriately can improve production efficiency while maintaining the quality of the shot peening layer. Conversely, reducing the spray gun feed speed and the number of shot peenings will negatively affect the quality of the shot peening layer and is not recommended.