Wear-resistant seamless steel pipes have become an indispensable component in various industries due to their exceptional durability and reliability. These pipes are specifically designed to withstand high levels of wear and tear, making them ideal for applications that involve the transportation of abrasive materials or fluids.

One of the key advantages of

wear-resistant seamless steel pipes is their ability to resist corrosion. The seamless construction eliminates weak points where corrosion can occur, ensuring a longer lifespan and reducing maintenance costs. Additionally, these pipes are manufactured using high-quality materials such as alloy steel or carbon steel, which further enhances their resistance to wear. Another significant benefit of wear-resistant seamless steel pipes is their ability to handle extreme temperatures and pressures. They can efficiently transport hot fluids or gases without compromising structural integrity. This makes them suitable for use in industries such as oil and gas, mining, and chemical processing. Furthermore, these pipes offer excellent dimensional accuracy and smooth internal surfaces, minimizing frictional losses during fluid flow. This not only improves efficiency but also reduces energy consumption.

Test results and analysis

According to the on-site heat treatment process, samples were taken for hardness testing after quenching and tempering hardness and tensile properties testing. The results are as follows:

From the experimental results, the outer hardness is slightly lower than the inner hardness, and the hardness is greater than 40HRC, which meets the requirements for hardness of wear-resistant pipes. To further explore the performance of the steel pipe, the microhardness and metallographic structure were also measured.

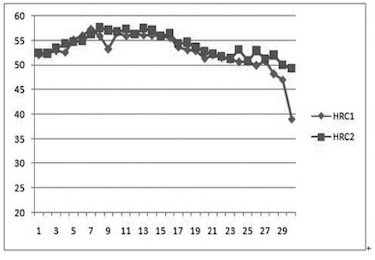

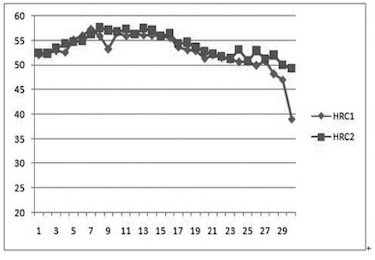

Figure 1 shows the microhardness, with a total of 2 lines. The data shows the Rockwell hardness from the inner wall to the outer wall, with a total of 30 points. It can be seen from the metallographic picture in Figure 2 that proeutectoid ferrite appears on the inner wall, and this is also well reflected in the microhardness curve. Going from the inner wall to the middle, the hardness shows an upward trend. Since only the inner wall is quenched, the temperature drop of the outer surface is relatively slow, and the hardness shows a relatively obvious downward trend. However, the overall hardness has reached above 5OHRC, especially the inner wall that requires good wear resistance.

Figure 1 Microhardness

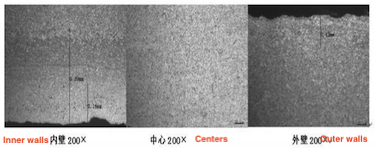

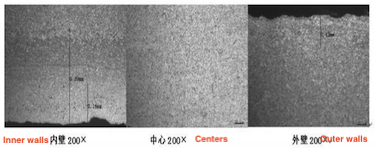

The metallographic picture is shown in Figure 2. There is obvious ferrite at 0.16mm below the inner surface and 0.13mm below the outer surface. It should be caused by the temperature drop being too great before quenching and falling below the Ar3 line. These ferrites will degrade the hardness of the steel and affect wear resistance; the core is hardened, adding a small amount of bainite to a uniform tempered martensite structure.

Figure 2

Summary

This wear-resistant pipe is made of a single material and has a simple production process and structure. It takes into account the good wear resistance of the inner wall and the good plasticity, toughness and weldability of the outer wall. The length of a single steel pipe can reach more than 12 meters, which is especially suitable as a wear-resistant pipe for long-distance transportation.