Abstract: Through the electron microscope scanning analysis of the warped skin of steel pipes, the possibility of the quality problem of the billet due to improper protection pouring in the continuous casting process of the billet was ruled out; through the analysis of the metallographic structure, combined with the basic quality of the inner and outer surfaces, it is determined that the tube blank heating process is operating normally. Through the analysis of inclusions, the quality problems of the tube blank caused by improper operation of the smelting process are ruled out; through the analysis of the decarburization layer, it is determined that the original crack of the tube blank is caused by the warped skin of the steel pipe.

Introduction

The round tube billet produced by Xingang Special Steel Co., Ltd. by continuous casting is supplied to a domestic seamless steel pipe company. It was heated in a circular furnace, pierced by a two-roll cross-rolling piercing machine, rolled by an Assel pipe rolling mill, sized and other processes to produce

seamless steel pipes of 139.7mm x 32.9 mm. After inspection, it is found that there is warped skin on the surface. To improve product quality, the steel pipe with warped skin was analyzed to find out the cause.

The surface of the hot-rolled seamless steel pipe is warped. The reasons for the formation of the warped skin of the hot-rolled seamless steel pipe are as follows:

① There is a problem with the surfaces of the tube billet.

② The steel pipe is mechanically scratched in the piercing and rolling process.

③ The poor heating quality of the tube billet causes the metal surface to break in the subsequent piercing and rolling process.

The poor surface quality of the pipe is mainly manifested as cracks and slag inclusions on the surface. Cracks on the surface of the tube blank split the metal on the surface of the tube blank, destroying the integrity of the metal. When the tube blank is perforated by the second silver cross-rolling, the metal at the crack is rolled, expanded, and layered to form a warped skin. Torsional deformation happens in the skew rolling and piercing process, so the outer skin is distributed on the surface of the steel pipe with a large spiral shape; the position corresponds to the crack of the pipe, and its size and number are irregular. At the same time, cracks on the surface of the tube blank go deep into the metal of the tube blank. In the heating process of the tube blank, the cracks directly expose the metal inside the tube blank to the furnace gas. Since the tube blank is generally heated at a high temperature of about 1200 °C, and the larger the diameter of the tube blank is, the longer the heating time becomes, which will cause obvious oxidation and decarburization of the metal at the crack, and the ferrous oxide produced by heating at the crack of the tube blank will be wrapped by the layered and overlapped metal after the tube blank is pierced and rolled. The slag inclusion on the surface of the tube blank is formed by pressing the casting powder into the surface of the tube blank due to improper operation in the continuous casting process of the tube blank. The slag inclusions on the surface also split the metal on the surface of the tube billet. After piercing and rolling, the tube blank with slag inclusions on the surface will also form a warped skin of the steel pipe, and its appearance is similar to the warped skin formed by surface cracks. The difference is that the slag inclusion on the surface does not directly expose the inner metal of the tube billet to the furnace gas in the billet heating process, so it will not cause oxidation and decarburization of the inner metal. In addition, the casting powder contains calcium, magnesium, sodium and other elements, and their existence can be confirmed by electron microscope analysis. At the same time, the currently used casting powder contains about 10% carbon, which makes the metal matrix near the slag inclusions form a thin layer rich in carbon zone. According to these characteristics, using electron microscopy and metallographic analysis, the warped skin caused by cracks and slag inclusions can be distinguished.

Mechanical scratches occur during piercing and rolling, such as holes in the rolls. When the metal is rolled on the rolls with holes, metal protrusions will be formed on the metal surface, and this raised metal will be flattened in the subsequent rolling process, forming warped skin. However, this kind of warping skin has a regular distribution; the shape is similar, and the spacing is equal to the circumference of the roll. The regular distribution of the warping skin can generally be judged to be mechanical scratches in the production process of the steel pipe.

The poor heating quality of the tube billet may also cause the outer skin of the steel tube to warp. When the tube billet heating furnace is not operated properly, the temperature in the furnace is uneven. The partial temperature of the tube billet is too high. If there are large low-melting point inclusions in the steel (generally distributed at the grain boundary), when the heating temperature reaches the melting point of the inclusions, the inclusions will melt at the grain boundary, that is, overburning of the tube blank. In the piercing and rolling process, the surface of the heated and burnt tube blank cracked to form warped skin. By observing whether there are oxidation products at the grain boundary of the matrix structure at the defect site, it can be determined whether there is overburning in the heating process of the tube blank.

1.

Basic situation of warped steel pipes

It is understood that the batch of steel pipes was fed about 50t, and there were 12 steel pipes with warped skin, weighing about 10 t.

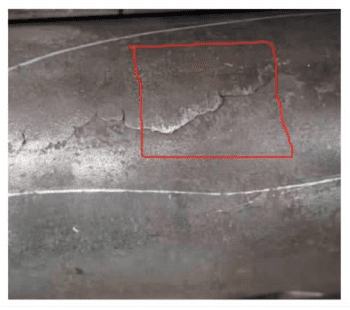

Different steel pipes have warped skin on different parts, and the size is different; the distribution is also irregular. This situation does not conform to the characteristics of mechanical scratches in the production process of steel pipes. Therefore, mechanical scratches should be ruled out first. Observe the sample tube with the naked eyes, and the warped skin is distributed on the outer surface of the steel pipe with a large spiral shape. The other parts of the outer surface of the steel pipe are smooth and free of defects. There are no quality defects such as inward folds caused by improper adjustment of the rolling mill during the production of steel pipes.

Figure 1 Warped skin on the steel pipe

2.

The preparation of the sample

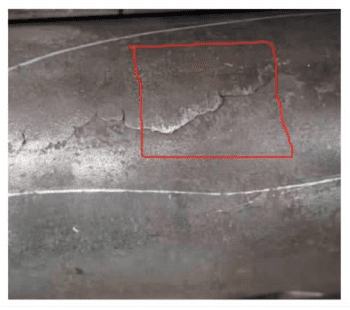

Cut the warped skin of the steel pipe transversely to make the sample in Figure 2. It can be seen from Figure 2 that the warped skin is a layer of thick skin covering the surface of the steel pipe. From the cross-section, a crack of about 47mm is formed between the warped skin and the metal matrix interlayer of the steel pipe. The thickness of the root of the warped skin is about 3 mm.

Figure 2