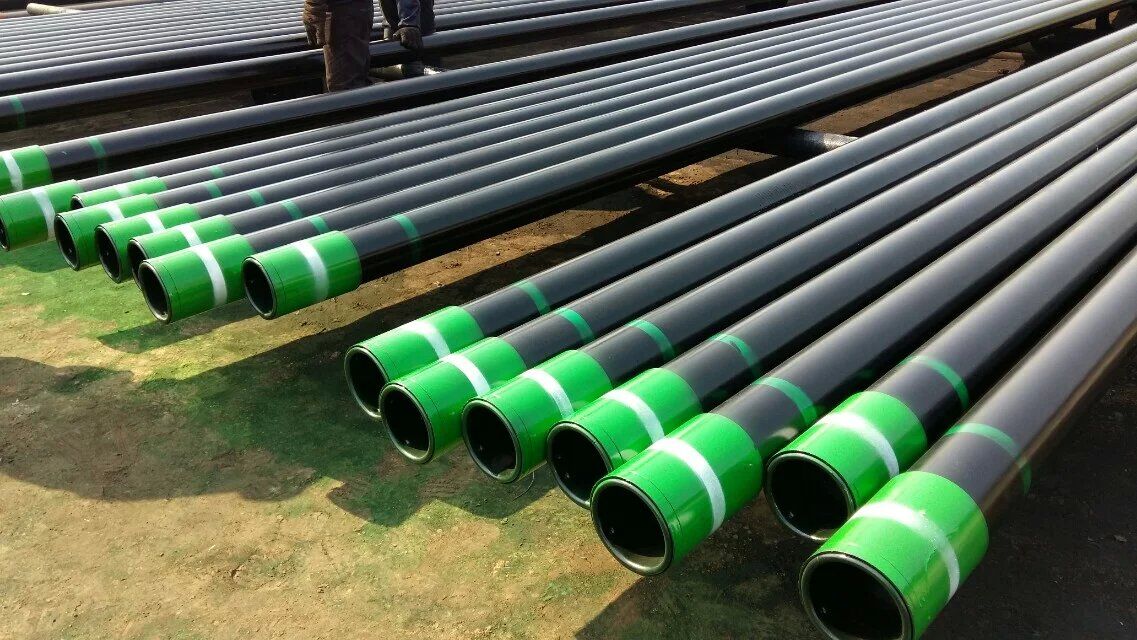

The OCTG pipe refers to the seamless tube used in oil wells. Its manufacturing methods are the same as seamless tube, domestic industries use steel to produce, such as DZ (geology) 35 ~ DZ55, etc. There is a thread on both ends of the steel tube, for combining with joint. In order to ensure the joint sealing, this kind of method has strict requirements on the thread accuracy.

1. Application

OCTG pipe used in oil well tubing.

2.Categories

According to SY/T6194-96 oil tubing and its connectors, homemade tubing is divided into the oil tubing without thickening and the oil pipeline with thickening at both ends.

3. Specifications and Appearance Quality

(1) The specifications as stipulated in the SY/T6194-96, usually their length (indefinite feet) are 6, 6.5, 7.5, 8.5 and 9.5 m.

(2)The steel tube without thickening at ends and its joint radius: 11/2 in、2 in、21/2 in、3 in、31/2 in and 4 in.

(3) The steel tube with thickening on both ends and its joint radius: 1 in、11/4 in、11/2 in、2 in、21/2 in、3 in、31/2 in、4 in.

(4)As stipulated in the standard, the appearance quality of the internal and external surfaces of the steel tube shall not be folded, roller, crack, separation layer, hair cracking, scarring and deep defects. The defects on the surface of the steel tube can use file, grinding wheel or other ways to remove, the depth of remove shall not exceed 12.5% of the nominal wall thickness. Defects shall not be repaired by welding or filled in any other way.

4.Chemical Composition Inspection

(1) The number of steel pipe and the joint of steel should be the same, with DZ35, DZ40, DZ50 or DZ55 steel manufacturing. The content of sulfur and phosphorus shall not exceed 0.045%, the content of arsenic should not exceed 0.15%. According to the regulations of GB222-84 to sampling; according to the relevant part of the GB223 to make chemical analysis.

(2) The American Petroleum Institute standards APISPEC5CT1988 years version 1 stipulated that chemical analysis measurement should be performed according to the latest version ASTME350 .

5.Physical Performance Test

(1) Tensile test should be taken according to the provisions of GB228-87. Hydraulic test have clear requirements according to different steel grade and steel tube radius. The inspection of tubing thread has strict requirements, according to the radius of steel pipe.

(2) The American Petroleum Institute standards APISPEC5CT1988 years version 1 stipulated that tensile test, flattening test, hydraulic test, sulfide stress corrosion cracking test, determination of grain size (according to the latest version of the ASTME - 112), transverse impact test (according to the latest version ASTMA370, ASTME23 provisions), hardness test (by ASTME18 the Rockwell hardness test standard method of metal materials.

6.Main Import and Export Situation

(1) Main import countries of tubing are Japan, Argentina, Switzerland, Spain also have a small amount of imports. Import standards with reference to the American Petroleum Institute (API) standards. Generally adopt API5A (J - 55 N - 80); 5 AK (P - 105); 5 AC (C - 75); 5 AJ- 55 NUE. Specification is 60.3 * 4.83 mm * R - 2; 88.9 * 6.45 mm * R - 2; 73 * 5.51 mm * R - 2.

(2) According to the American petroleum institute standard APISPEC5CT1988 in version 1, steel grade is divided into 7 types: H - 40; J - 55; N - 80; C - 75; L - 80. C - 90; P - 105. Tubing pipe end should have thread and coupling or supplied by the following forms: plain end, threaded end without a collar, overall connection, special end processing and sealing ring structure.

7.Packing

In order to protect the steel tube and screw thread joints, regardless of whatever packaging (packed in boxes or bulk), tubing and its joints shall be screwed on protection ring.